Features & Benefits

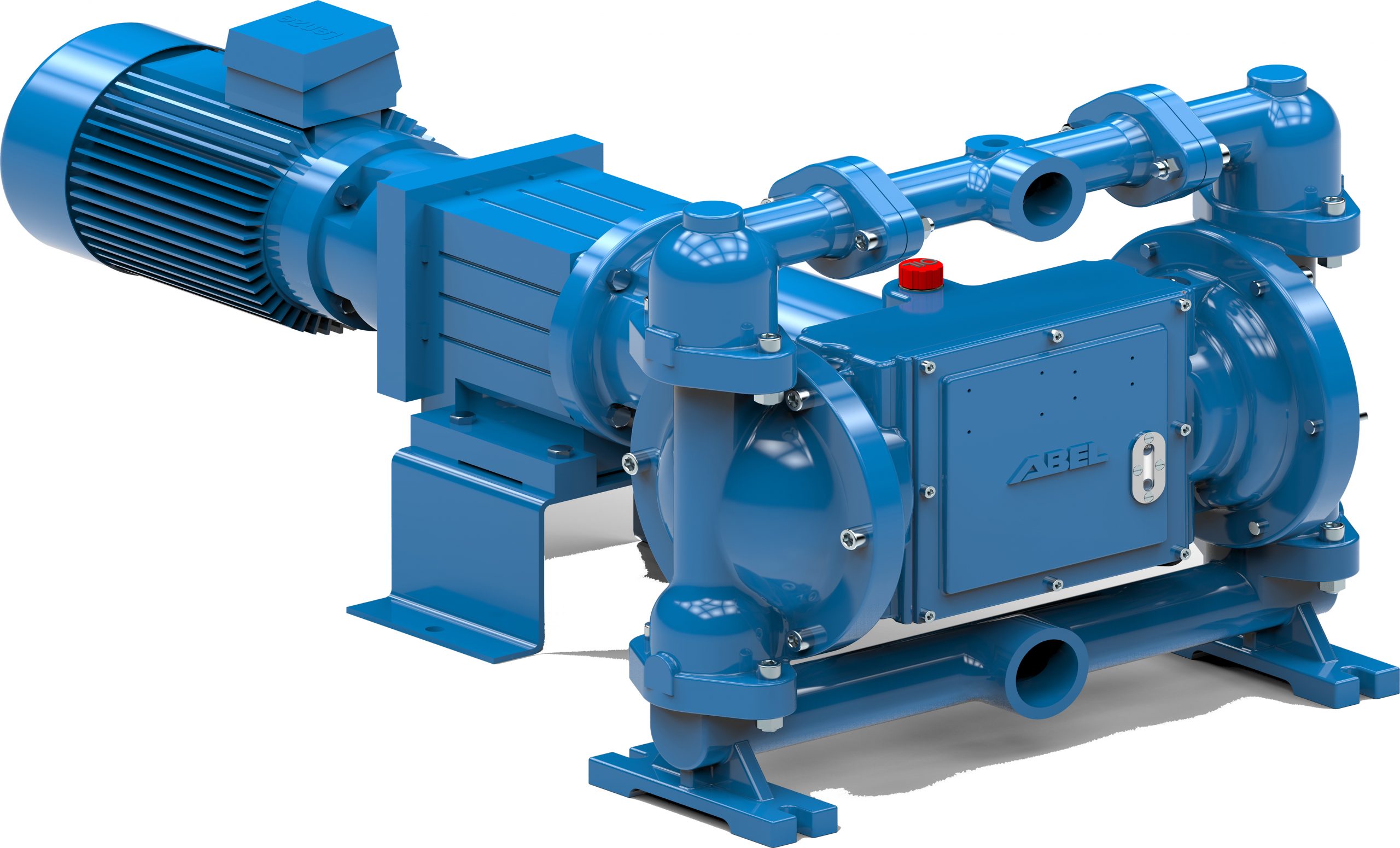

ABEL EM electrical diaphragm pumps are available in several basic models with 50 total combinations, guaranteeing your requirements will be met for a wide range of applications. Additionally, you can choose from a metal or plastic encasing. Several features come standard across these models and combinations.

Standard Features of ABEL EM Electric Diaphragm Pumps

- Highly energy-efficient design and functioning.

- Seal-less, dry-running, low shear, versatile fluid handling capacity of traditional diaphragm pump design.

- Efficient electric drive.

- Constant flow rates adjust to variable pressure and viscosity.

- Port size up to 6” for maximized flow rate.

- Fully enclosed diaphragms with no material exposure.

- Robust and comparatively compact design and footprint.

- Smooth product transfer.

- Highly reliable, dry running functioning.

- Optional: VFD flow control improves pressure performance. Pulsation dampeners and other accessories.

ABEL EM Metal

- Extended lifecycle due to robust design.

- Performance ranges up to 60 m(3)/h (265 GPM), up to 0.8 MPa (115 psi)

- Housing construction consists of ductile iron (SG), stainless steel (ED), and aluminum (AL).

- Diaphragm/ball/seat options:

- BUNA-N/NBR

- EPDM

- Polyurethane (for ball and seat construction only)

- FPM (Viton®)

- PTFE

- Flap valves for larger solids

ABEL EM Plastic

- Suitable for aggressive media

- Performance ranges up to 20 m(3)/h (90 GPM), up to 0.8 MPa (115 psi)