Why Choose Brabazon For Your Compressed Air Audit?

We guarantee to identify savings in excess of the Audit Cost or it is free!

We back our recommendations with a performance guarantee!

- We identified over $20 MILLION dollars of savings for our customers.

- Typically 75 of 100 surveys identified savings in excess of 25%!

- Audit is performed by a certified air system auditor – not a salesperson or service technician.

- We can provide ANY solution – So the results are truly independent and not skewed toward any particular solution in advance.

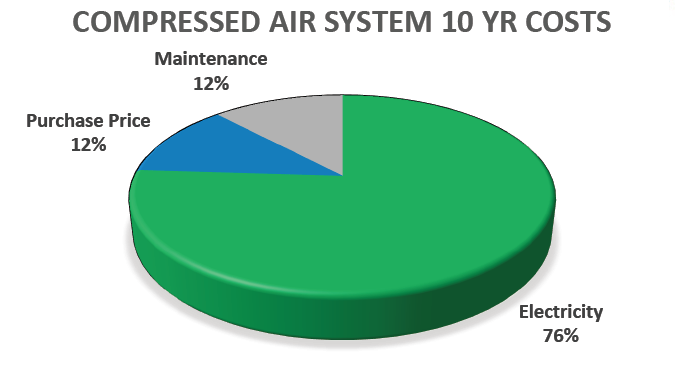

- We measure true kW – not just amps which can be off as much as 25% on some compressors.

- We provide more useful data, charts and graphs.

- Our data loggers can record up to 2 weeks – longest in the industry.

- Our data loggers take samples every one second – greater than industry average.

Brabazon has the right solution for you!

Walk-through

A one week snapshot of your system performed by a salesman or service technician. We monitor amps and pressure in the compressor room. A computer-generated report delivers flow rates, pressures and basic solutions. Graphs are included for all collected data.

Supply Side Assessment

Supply Side Assessment

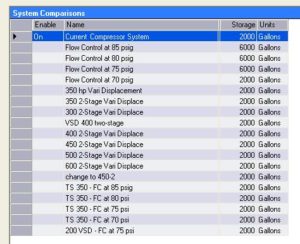

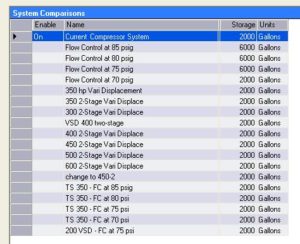

A one week analysis of your air compressors performed by a certified auditor. We monitor amps and pressure in the compressor room. Detailed hand-generated reports and graphs deliver supply side analysis, flow rates, pressures and custom solutions. A percent capacity chart illustrates how heavily loaded your air compressor is and the percent pressure chart allows you to hone in on production and scrap issues.

Demand Side Audit

An exhaustive multiple day analysis of your air system and operations performed by a certified auditor. We monitor kW and pressures throughout your plant. You’ll receive an extremely detailed, hand-generated report that delivers a complete evaluation of your air system and illustrates how you can reduce your demand for compressed air. Many customers have changed entire manufacturing processes as a result of this type of analysis.

Leak Audit

An Ultrasonic leak detector is used to identify leaks throughout your plant. Leaks are tagged and color-coded according to severity. Your leak load and its associated energy cost are calculated. BRABAZON exceeds the guidelines established by the DOE.

* Rebates may be available to cover some or all of the audit cost.

Brochure Download

Schedule an Audit of your Industrial Compressed Air and Vacuum System

View Locations

Supply Side Assessment

Supply Side Assessment