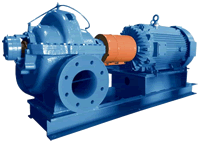

Features & Benefits

Because the KP range of a PACO KP/KPC series centrifugal pump features double volute construction, self-contained bearing housing, and your choice of application specific materials for construction, their quality is favored by engineers. With so many customizable configurations, you can be sure to modify this pump to meet accommodate your requirements.

Standard Features & Benefits of the PACO KP/KPV Series Centrifugal Pump

Bearings

- A large diameter shaft and a short bearing span provide a minimum life span of 10 years.

Sleeve Bearing

- Contaminates and particles are flushed by spiral grooves to reduce maintenance costs.

Sleeve Bearing Housing

- Pump life is extended due to the 360-degree machined register constructed to simplify removal.

Bearing Housing

- 360-degree machined register fit minimizes shaft deflection and makes for easy alignment.

- Seal and bearing chambers are combined to simplify maintenance.

- Seal, sleeve, and bearing inspection are accomplished without the need to remove the top half of the casing.

Case Wear Rings

- Protect pump casing from damage and allow for easy maintenance of proper running clearances.

- Reduce maintenance costs and help to maintain efficient operation.

Casing

- Suction and discharge flanges are integrated into the lower casing half to allow for the removal of the rotating assembly without disturbing the piping.

- Vibration is minimized by a sturdy base, extending the overall life of KPV.

Impellers

- “Closed (double-shrouded) with Francis Vane.

- Noise and vibration are minimized with double volute design, extending the deal and bearing life.