Features & Benefits

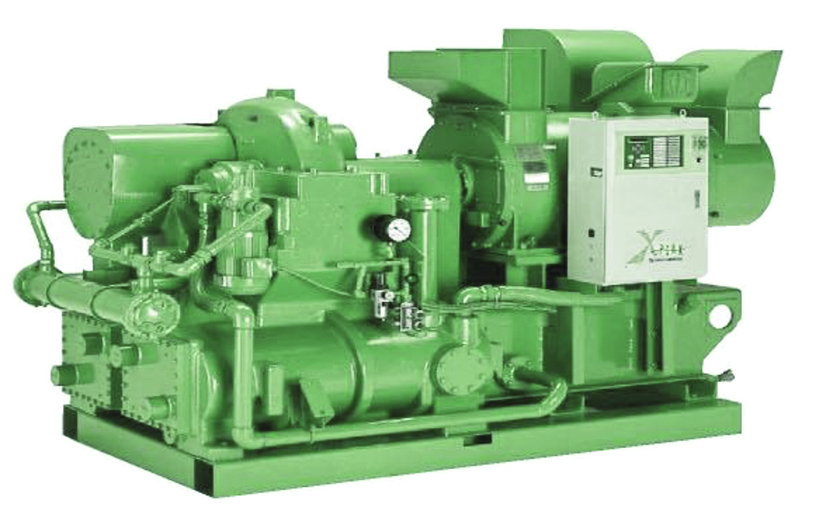

The Sullair T-Series air compressors are the optimal choice for customers looking for a simple, high-performing design.

Standard Features of the Sullair T-Series Air Compressors

- Energy Efficiency. Impellers are built with advanced technology that is specifically matched to the required airflow and pressure allowing for considerable energy savings.

- Low Maintenance Costs. Non-contact internal components require minimal periodic maintenance and all moving parts are easy to access and inspect simply by removing the gear cover.

- Reliability and Durability. The time-proven design has achieved unparalleled reliability and durability with strength that is heavily resistant to corrosion and wear.

- Class 0 Oil-Free Air. To benefit applications where air purity is essential such as pharmaceuticals, food and beverages, electronics, automotive painting, and textiles.

Different Elements of Advance Technology

- Inlet Guide Vane/IGV. With inlet airflow that moves in the same rotational direction as the first stage impeller, less power is needed to deliver airflow and pressure. IGV is able to guide gas flow direction so up to 10% of power consumption is saved when not in full load operation.

- Gear Box. The gear box is a single piece that has integrated coolers allowing for a more stable design that reduces vibration. It is horizontally split for easy access and inspection and the intercooler and aftercooler bundles are easily removed for cleaning. Each element of the gear box is treated with an epoxy coating to avoid corrosion.

- Power Coupling. The safety protection cover provides easy access for maintenance with a dry stainless steel disc coupling that requires no lubrication.

- Coolers. Also easily accessible with no risk of disturbing other components, the cooler tube bundles are made with a water-in-tube design.

- Aerodynamic Inlets. Inlets are specially treated with an epoxy coating to avoid corrosion.